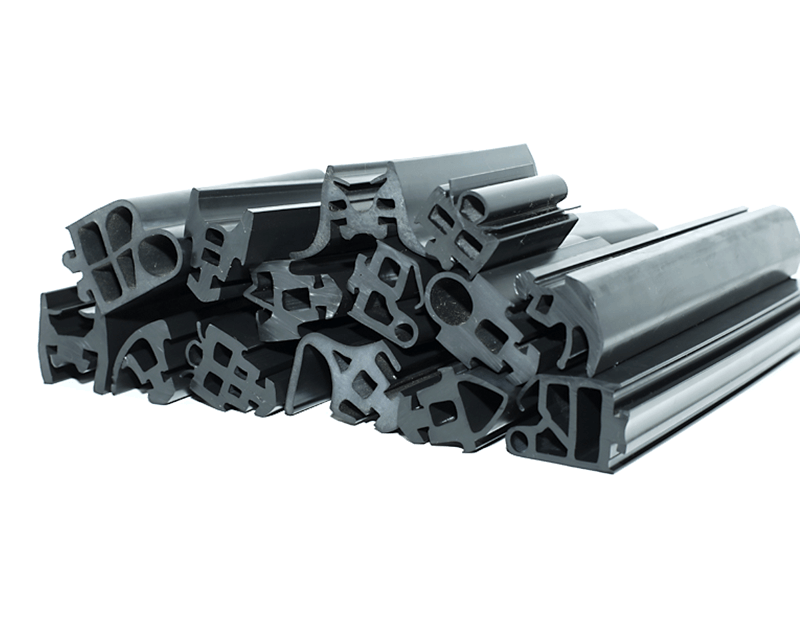

About Our Extrusion Technology

We have advanced fully automatic extrusion equipment and a strong R&D team, and we can customize rubber sealing strips for you free of charge.

Hey!

I'm Henry from Guangzhou Gravity Industrial Co., Ltd.. Let me guide you through the pages.

I am a CEO of Guangzhou Gravity Industrial Co., Ltd.I have been working there for 20+ years. Click the button below to find out how we can provide you with a great solution for sealing strips.

FREE CAD Design

All your customization needs.

- We can meet all your custom extrusion sealing needs

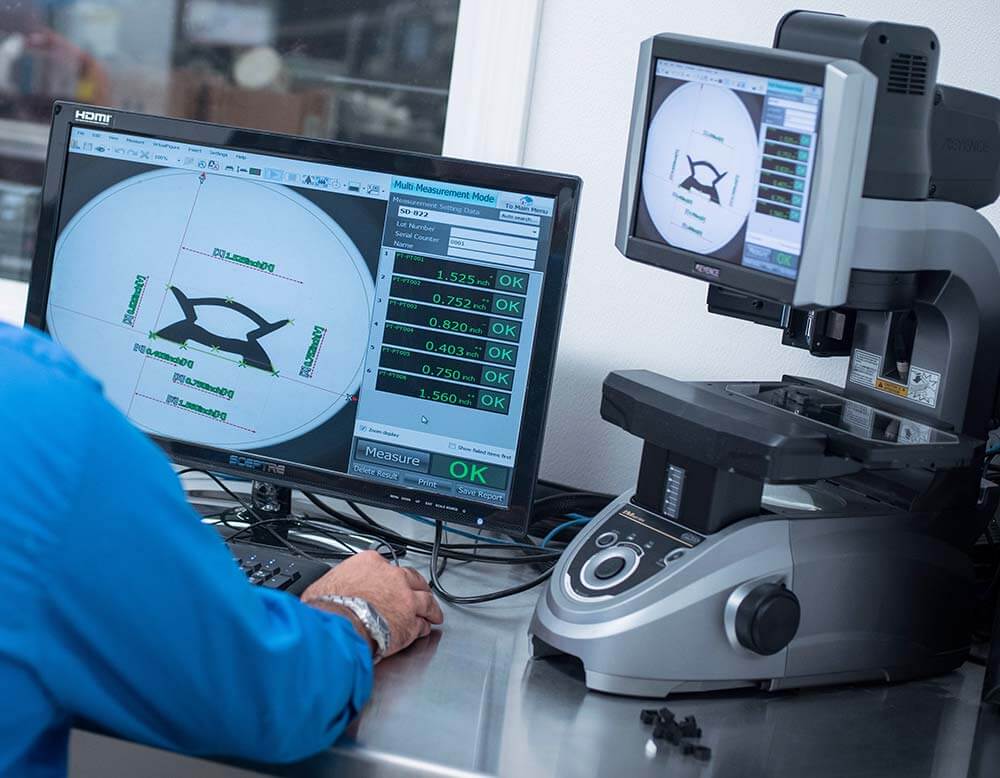

We have 5000+ molds. Precise control of size. Excellent researcher and CAD drawing skills. This makes our factory very flexible. That is precisely what sets us apart. Regardless of your industry, the complexity of your requirements, your material preferences, or the dimensions of your rubber parts?

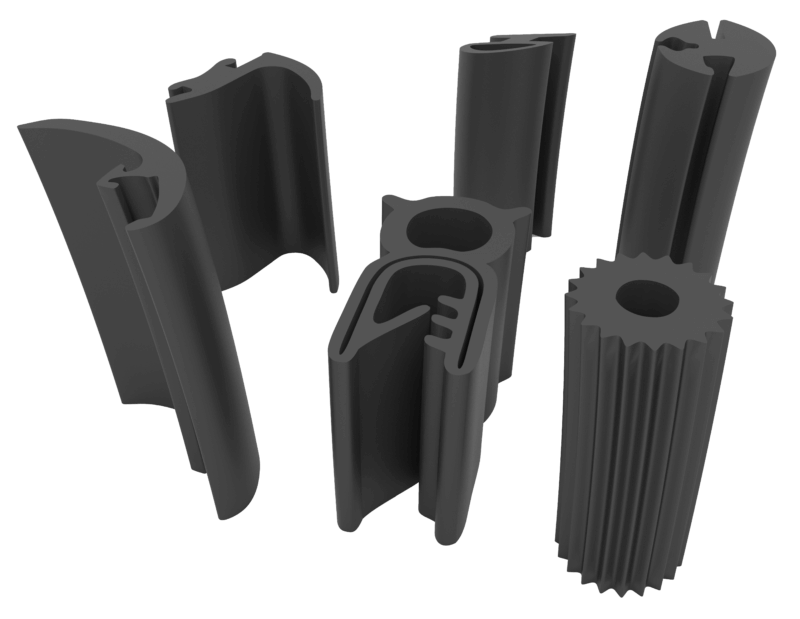

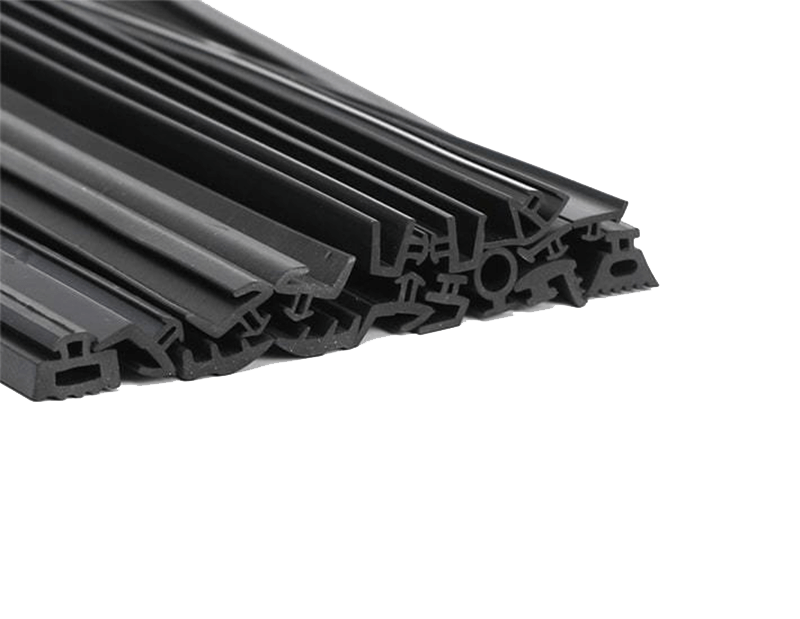

Extruded Rubber Parts

We can custom extrude any shape, color, or material seal. Based on CAD drawings for all your customization needs.

Automotive Seal

We can provide design

- flocked glass run channel

- Sponge Bulb Extrusion Seal with Metal Carrier

- edge guard trim seal

- Extruded glazing rubber gasket seal

- self-adhesive door seal, etc.

Bus/Truck Seal

EPDM rubber is the first choice

- the price that is competitive

- decided by the performance of EPDM material

- Provide you with solutions for custom complex products.

- Customize all your challenging seals.

Container Seal

Hot vulcanized corners

- available for container and refrigerated door sealing strips.

- Type: C type gasket, H type door gasket, J type door gasket

- A custom container door gasket is also available for your needs.

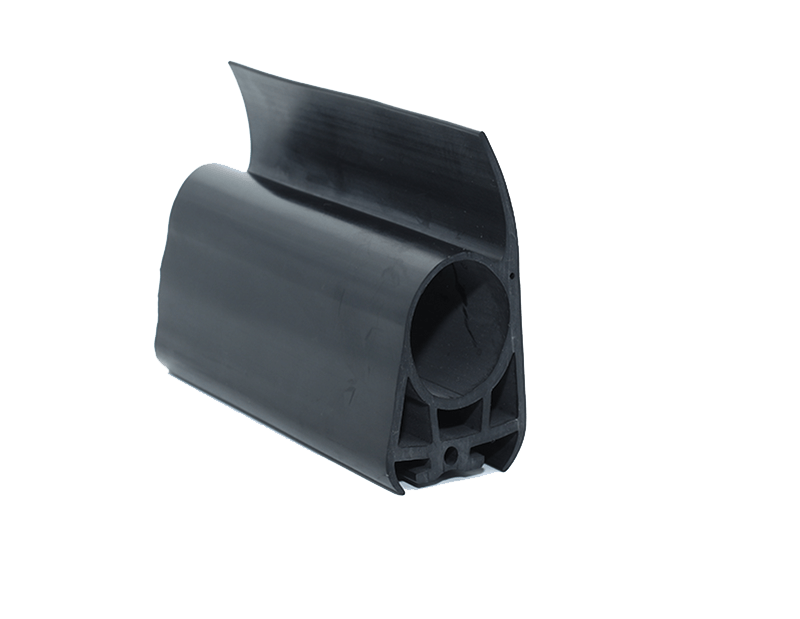

Marine Seal

Rubber dock fenders extrusions

- EPDM rubber with good resistance to weather, UV, ozone, water, and chemicals…

- with the best quality rubber

- We can according to the customer’s drawing to produce

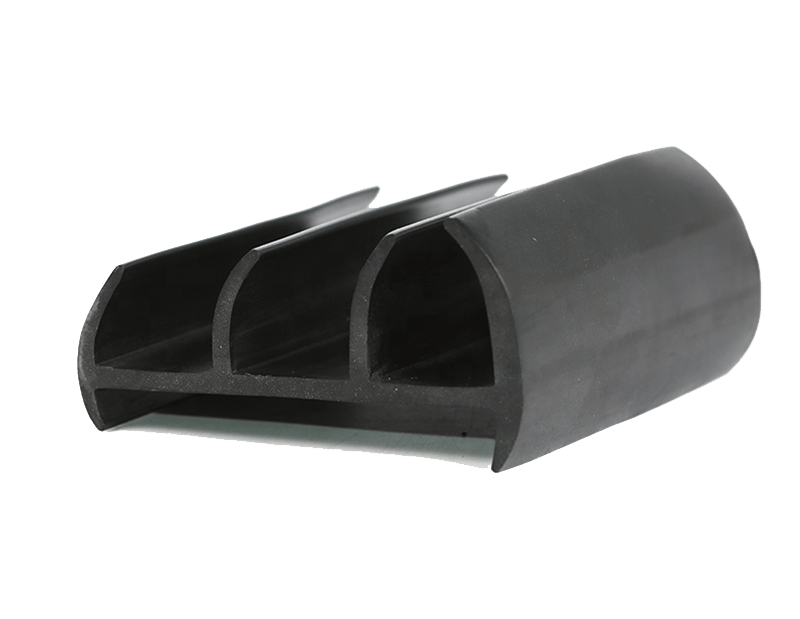

Industrial Door Seal

We provide a wide range of seal strips

- extruded sealing strips

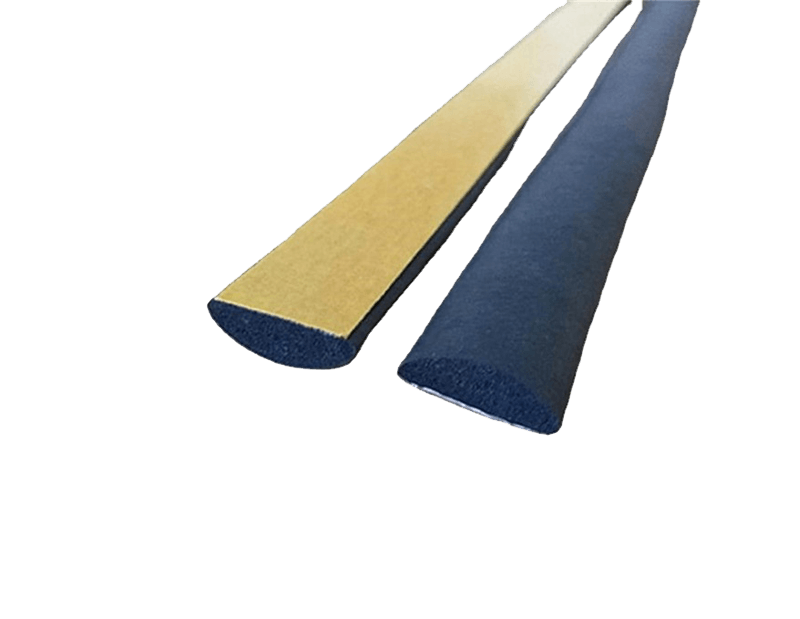

- sponge profiles

- dense extrusions

- flocking sealing strips

- glazing channels

- edge trim seals, etc

Fire Resistant Seal

A fire-resistant rubber seal strip——EN45545

- is a high-quality EPDM rubber seal strip

- has replaced existing rubber seal strips in a number of trains across the country

- This EPDM seal strip conforms to the new British standard EN 45545

Construction Seal

500+ construction related challenges have been successfully solved,

- extrusions are used directly as a construction material

- a wide range of custom-made installation tools can be developed to help lower installation and construction times, saving our clients a significant amount of time and money.

Electrical Cabinet Seal

They’re installed inside cabinet-like enclosures

- weatherproofing

- flame or chemical resistance

- EMI shielding

- They can also help engineers meet IP standards, NEMA rating, or UL 94 requirements

What Are You Looking For?

Whatever your product all shapes, sizes, and complexities meet your specific needs.

OUR CAPABILITIES

We use state-of-the-art machines. Has the following capabilities in rubber extrusion:

- Cutting

- Vulcanized Splice

- Adhesive Tape

- Miter Cuts

- Custom Compounding

- Dense and Sponge Materials

- Dual Durometer

- Microwave

- Autoclave

- Mandrel Cure

MATERIALS

Since inception.We can produce extruded seals from the following materials:

- Ethylene Propylene Diene Monomer(EPDM)

- Polyvinyl chloride (PVC)

- Silicone

- Neoprene(CR)

- SBR

- Thermoplastic Elastomer(TPE)

- Thermoplastic Vulcanizate(TPV)

- Thermoplastic Rubber(TR)

- Natural Rubber

- Solid and Sponge

Rubber extrusion

Things need to consider

The most significant procedure parameters are pressure of the head, speed of extrusion, and temperature. They are the best pointers of how well or how inadequately the extruder performs. Procedure issues, as a rule, are first turned out to be clear from the head pressure and temperature readings.

Rubber extrusion provides a variety of benefits not found in other manufacturing processes

A wider variety of available shapes

Cost-efficient production

Lightweight products with high flexibility

Limited production waste

Rubber Extrusion Process

The rubber extrusion process involves forcing a rubber compound or mixed elastomer under pressure through a die that has the shape of the end product. The process starts with feeding material into an extruder, where heat and pressure are applied to aid the material’s travel through the die. Depending upon the material used, the heat and pressure will expand the end product’s size.

Steam Curing

Steam curing is mainly used for smaller batches and when the material being used contains non-black compounds. Curing with steam rather than with chemical cures is advantageous because it is considered a safer way to vulcanize rubber. Through steam curing, materials have significant wear performance properties, especially when using bonding in future installations.

Continuous Curing

Continuous curing is used on larger quantities or larger physical sizes of products. This technique uses microwaves or salt bath processes to gradually cure the rubber. Continuous curing is a low-energy technique because only a small amount of energy is applied over time. This process also ensures greater consistency of the profile of the end product.

Cutting-To-Length

Cutting-to-length is used to cut material away to achieve the desired shape of the end product for close tolerances. Lathes, high-speed cutters, and rotating cutters are used on longer runs and larger physical sizes of products. Other cutters can be used on long continuous runs and guillotine cutters are used on long-length and larger cross-sections.

Splicing

Splicing is used as a more cost-effective way to produce an endless loop product with an extruded profile or other products with complex corners because it requires no expensive custom tooling or dies. The process starts by utilizing our other methods of production to make the components of the final product. These components are cured using one of our curing techniques and cut, if needed, for final assembly. Depending on the desired shape of the final product, the materials can be spliced using cold bonding or splice molding.

Hot Splicing / Vulcanizing

We use the hot splicing/vulcanizing process to facilitate a chemical connection between the ends of rubber extrusion, creating a full and connected seal that improves the strength of gaskets and enhances their resistance to weather and other environmental factors.

Rubber Lathe Cutting

The lathe cutting process involves extruding a tube of rubber, cutting it to a specified length, and sliding it onto a mandrel. The part is then ground at high speed on the outside diameter (OD) using a lathe. We use advanced grinding and lathing machinery to ensure that the OD of the tube matches the customer’s specified tolerances. Washers and gaskets requiring precision or high-precision tolerances are ideal for lathe cutting. Most rubber materials available today are compatible with the lathe cutting process. The benefits offered by lathe cutting include substantially reduced material waste, no tooling costs, improved sealing surface, and no hour glassing from die cuts.

These parameters relate just to the extruder

In any case, there are a lot more procedure parameters for the whole extrusion line and this, obviously, relies upon its particular segments.

Line speed

Dimensions of the extruded product

Line tension

Other significant extrusion procedure parameters are:

- Design of the die

- Proper land length

- Land length ratio

- Drawdown

- Screw speed

- Motor load

- Barrel temperatures

- Die temperatures

- Cooling rates

- Vacuum level invented extrusion

- Designing for sensitive materials

What You Should Know?

Two types of vulcanization method

The final product is produced; in the discontinuous vulcanization, the standard of the rubber sealing strip is that the finished product should be soft, not too rigid, smooth, and smooth on the plane, and there should be no babble.

Discontinuous Vulcanization

- After cutting the extruded rubber strip to a certain length,

- Put into vulcanization tank to vulcanize

- Put the extruded rubber strip semi-finished product into the model to vulcanize

Continuous Vulcanization

- microwave continuous vulcanization

- Salt bath continuous vulcanization method

- hot air continuous vulcanization

Why Choose Us

REAL FACTORY

We are an enterprise integrating design, production and sales, with many years of experience in technology research and development.

FAST DELIVERY

4 production lines work at the same time. No matter how many meters you customize. We can produce quickly and ship on time.

EXPERIENCED DESIGNERS AND ENGINEERS

We have been in the extrusion weatherstrip industry for 20 years. By thinking, designing, making, collaborating. Provide the perfect solution for your customized products.

STATE-OF-THE-ART MANUFACTURING

Benefit from our ultra-modern extrusion equipment to create the perfect profile for your application. We offer custom shapes, specialty rubber compounds, as well as secondary manufacturing and assembly services.

CERTIFICATES POSSESSED

We have ISO9001:2015 Quality Management System, EN45545-2 Flame retardant performance test report, DIN5510 Flame retardant performance test report, etc.

YOU CAN EARN HANDSOME PROFITS IN YOUR COUNTRY

Sourcing from the factory saves you money. We have helped customers in more than 30+ countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

Our factory

Get FREE Sample Today!

We’d Love To Hear From You! For Inquiries About Our Products. Please Leave Your Email To Us And We Will Be In Touch Within 24 Hours.

Some cool tips you should know

01.

What is the life expectancy of the rubber seal?

The service life of rubber seals depends on a variety of factors, including the environment, cycles, pressure, etc. You can conduct accelerated life testing to determine the expected service life, but it must be conducted in dynamic applications.

02.

Can I return it if the sale is not good?

Can not. There is no way for the rubber seal to return to rubber. This is an irreversible result.

03.

How many employees do you have?

We're expanding fast. We currently have 100+ employees and 3,000-5,000 square meters of factory space ready to serve you.

04.

Payment methods you care about?

We accept T/T B/L or L/C at sight, West Union, VISA, Paypal is also accepted.

05.

What is the normal lead time for product orders?

Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10 days, and average production time after sample approval is 2-3 weeks.

06.

Could you please tell us the month capacity of your products ?

It depends on which model, we produce more than 3000+ tons of materials per month.

07.

Could you please tell us the month capacity of your products ?

We provide preproduction samples before mass production for all customers. We provide quality certs We accept third-party inspection.